Services Include:

- Complete utility plant inspections (overhead and underground)

- Heat sources found on insulated equipment will allow DDP Technology to identify potential failure points or flash over conditions

- All Infra Red inspectors are certified

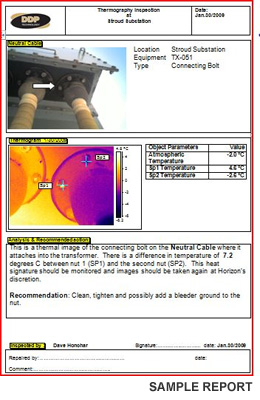

- Detailed report on components showing any excessive heat signature and recommendations

Infrared scanning detects a rise in temperature, thus allowing it to be used in a variety of applications, including during normal operations.

Infrared scanning is used to scan building envelopes, electrical components and connections for excess heat. When there is a presence of heat, this indicates resistance. In turn, cause of this resistance is most often related to failing components, poor connections, corrosion, load imbalance and/or harmonics.

Benefits

Many benefits can be derived from infrared scanning including:

- locating potential problems prior to plant start up

- reduced downtime and emergency repairs

- reduced labour required for preventative maintenance by locating specific areas that require repairs

- minimized scheduled maintenance times

- extended equipment life

- increased reliability of plant power distribution system

- permits the evaluation and verification of repair work

- prevention of accidents, personal injury and property damage.

INFRARED WINDOW INSTALLATION

No need to remove panels when performing IR Inspections

Drop down window allows for easy access when viewing electrical apparatus