CO2 dry ice cleaning is rapidly becoming the preferred method of cleaning among the industrial, commercial, utility, and environmental sectors.

Benefits:

- Online cleaning of various types of equipment eliminates the need of disassembly and shutdown, allowing operations to continue.

- Click here for a comparison of dry ice cleaning vs traditional methods

How does it work?

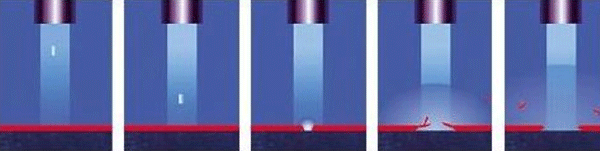

- Compressed air shoots the dry ice pellets out of a nozzle at -109.3 degree F or -78 degree C, somewhat like sandblasting or high pressure water or steam blasting, but with superior results.

- The dry ice “blasting” against the material to be removed causes it to shrink and loose adhesion from its subsurface.

- Additionally when some of the dry ice penetrates through the material to be removed, it comes in contact with the underlying surface. The warmer subsurface causes the dry ice to convert back into carbon dioxide gas. This gas expands up to 800 times its volume and expands behind the material, speeding up its removal.

The cleaning action of dry ice blasting is due to three factors:

-

- KINETIC ENERGY: Compressed air propels the dry ice particles up to supersonic speeds. Though light in weight, they puncture the contaminate and chip away at it, thereby opening the surface of the contaminate.

- THERMAL DIFFERENTIALS: An immediate and localized cold shock to the contaminate versus a substrate (surface) which cools down much less. This action promotes a contact break between contaminate and substrate.

- SUBLIMATION: As the dry ice sublimes (becomes a gas) on impact, it increases up to 800 times its volume from solid to vapour, when it enters the cracks within the contaminate. This gas expansion, breaking up the contaminate from within, is the major factor responsible for the Dry Ice cleaning effect.

How Dry Ice Cleaning Works

Instead of using hard abrasive media to grind on a surface, often causing damage, dry ice blasting uses soft dry ice, accelerated to supersonic speeds, creating mini-explosions on the surface to lift the undesirable item off the underlying substrate.

Instead of using hard abrasive media to grind on a surface, often causing damage, dry ice blasting uses soft dry ice, accelerated to supersonic speeds, creating mini-explosions on the surface to lift the undesirable item off the underlying substrate.